Agriculture is a fast growing sector when it comes to robotics and automation. Drones take off in a big way, helping farmers not only to quickly survey acres of crops from the air, but also to apply fertilizers and other chemicals. A single farmer equipped with a drone is faster than workers in the field. The targeted use of chemicals instead of surface sprayers also saves operators money. Developers design robots for all kinds of farming tasks, including picking berries. Another trend on the tech horizon is the use of insect robots, which has recently received a boost with the incorporation of jump mechanics inspired by click bugs.

“One of the biggest challenges in small robotics is finding a design that is small yet powerful enough to bypass obstacles or quickly escape from dangerous environments,” said Sameh Tawfick, a US-based robotics engineer. Previous studies had shown how click beetles use snapping to produce a rapid release of energy that propels the creatures into the air at heights over ten times their body length. Tawfick and colleagues worked to integrate such a mechanism into insect robots and discovered that their miniature prototypes could outperform nature. The team’s designs featured a cascade of dynamic buckling called jumping with unidirectional muscles and power amplification (JUMPA).

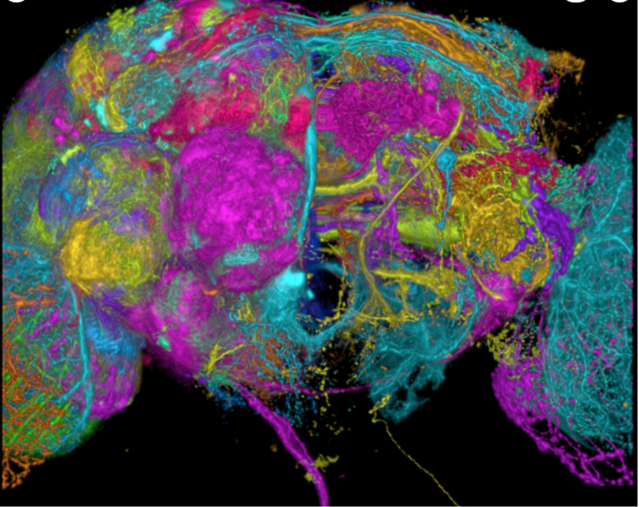

Jumping insect robots

The lightweight energy storage and release device, weighing just 1.6 g and 2 cm long, enables insect robots to jump 0.9 m in the air – 40 times their body length. According to the researchers, their configuration achieves the energy densities typical of the best macro-scale jumping robots. And at the same time, the performance of the mechanism corresponds to the rapid escape times of jumping insects. Tawfick and his staff are open to future applications. One idea is to equip the insect robots with cameras and use them to inspect areas that are difficult to access, such as cavities in engines. The ability to access tight spaces could also lead to designs being used for search and rescue.

Many industries could benefit from insect robots. “We also envision insect-sized robots being useful in modern agriculture,” Tawfick said. “Scientists and farmers are currently using drones and rovers to monitor crops, but sometimes researchers need a sensor to touch a crop or take a photo of a very small feature. Insect-scale robots can do that.” Miniature mechanical bots could patrol fields, jump into crops to check their condition and send back data.

Swarms of insects usually spell disaster for crops, but hundreds of tiny flying robots could serve as an innovative technology platform for distributed sensing. Last year we reported on the development of smart dust for data collection that could one day be used to detect gas leaks, locate trapped people – say, in a cave network – and other novel applications. Robots benefit from innovations not only in miniaturization and insect-like flight and jumping characteristics. Developments in tactile materials enable robots to be more sensitive to objects and pave the way for automating delicate operations like picking berries.

Smart rubber band

Tech startup Power On is commercializing the use of “smart elastic” made from dielectric elastomers. The material is ideal for making soft actuators and is sometimes referred to as “artificial muscle” due to its ability to contract in response to electrical impulses. According to the company, which operates in New Zealand – where the company was founded – and Germany, tactile arrays can be retrofitted to state-of-the-art industrial robotic grippers, allowing machines to feel and adjust their gripping force.

The tactile material consists of soft polymers and electrically conductive carbon and can be used in various ways to benefit robotics. Smart Elastic can be used as an actuator, as a tactile sensor array, and even for energy harvesting – for example, to recover some of the effort required for movement. Another development that expands the design options for manufacturers of all types of automation aids – from insect robots to industrial process equipment.

At a robotics festival held in Dresden, Germany last year, the Power On team demonstrated their tactile technology to attendees – a mix of industry leaders, researchers and entrepreneurs. The company has assembled a robotic hand capable of gripping a tennis ball to demonstrate the capabilities of criss-crossing smart rubber bands. And looking to the future, the company sees many more uses for what are being dubbed soft robots. In other words, machines with enhanced sensory responses. Industries that could benefit from soft robots include industrial automation – such as tasks involving fragile components – e-commerce, agritech, and healthcare.

“We see a future where everyone uses smart robots and soft devices in their daily lives, at work and at home,” the company writes on its website.