“It’s not how far you fall, but how high you bounce that counts.”

— Zig Ziglar

Chipotle Vice President of Food Safety Kerry Bridges joined in January 2019 to lead the company’s food safety/quality assurance team and food safety restaurant operations teams in Canada and Europe.

© Photo Courtesy: Chipotle

It has been nearly five years since the highly publicized foodborne illness outbreaks at Chipotle Mexican Grill, but those years have enabled the company to gain a distinct “bounce” that has significantly enhanced its food safety programs, while positioning it to proactively address the challenges associated with the COVID-19 pandemic.

Since 2015, Chipotle has introduced progressive food safety policies and procedures, and brought on new executive leaders to enhance its existing practices through farm-to-fork safety and quality measures. Among those new leaders is Vice President of Food Safety Kerry Bridges, who previously worked with Frank Yiannas at Walmart as senior director of supplier food safety. At the same time that FDA called Yiannas, who became Deputy Commissioner for Food Policy and Response in December 2018, Chipotle called on Bridges, who joined in January 2019 to lead the company’s food safety/quality assurance team and food safety restaurant operations teams in Canada and Europe.

Bridges’ work with Yiannas and Dave Theno, who is credited with having saved Jack in the Box after a massive foodborne illness outbreak, significantly advanced her own knowledge and experience in ensuring the food safety of a multinational food business. “I’ve grown up with some of the best in food safety,” Bridges said. “If ever there’s a situation I may not be prepared for, I have people to call on.’’

Additionally, she said, “In keeping up with all of Frank’s initiatives at Walmart, I got used to working with a business of that size.”

It also was at Walmart where Bridges was introduced to food safety culture — which she was pleased to find alive and well at Chipotle. “I really do buy in to how that defines success,” she said, adding, “I drank the food safety culture Kool-Aid.” But, in all seriousness, she added, “I got the message on convincing people how important food safety is — and that message doesn’t fall on deaf ears at Chipotle.”

While Bridges is now responsible for leading the food safety charge, she was provided with a bit of a road map, with food safety needs having been identified by Chipotle’s Food Safety Advisory Council, which was formed in 2016. Consisting of top food safety experts, the council includes former FDA Associate Commissioner of Foods Dr. David Acheson; former USDA Under Secretary for Food Safety Dr. Elisabeth Hagen, Ph.D.; former CDC Research Scientist and Chick-fil-A Director of Food Safety Hal King; and retired Chipotle Head of Food Safety and Meat Sciences Professor James Marsden. As independent, external experts, the Food Safety Advisory Council is charged with evaluating Chipotle programs, both in practice and implementation, and advising the company on ways to continually elevate its standards for food safety and ensure its food safety program is as robust as possible.

“The council did a great job identifying what needed to be done before I got there,” Bridges said. “So the first thing I did was put together a food strategy from that. There was a lot happening, but the team needed a strategy.” That “world-class” food safety strategy is based on six pillars: Remove Risk Early, Reduce Restaurant Risk Factors, Enhance Regulatory Compliance, Drive Global Consistency, Manage Emerging Issues, and Cultivate Food Safety.

Early risk assessment at Chipotle includes the use of natural antimicrobial wash of all produce, leveraging of inhibitors, and implementation of innovative processes.

© Photo Courtesy: Chipotle

Chipotle Supplier Intervention

To mitigate food safety risks in ingredients, Chipotle partners with its suppliers to implement rigorous food safety standards beyond regulatory requirements, designing additional controls to reduce or eliminate food safety risks before ingredients reach restaurants. Chipotle:

- Requires food suppliers to:

- Implement a series of preventive food safety systems, including HACCP plans and advanced technologies to further control food safety risks.

- Document the effectiveness of the food safety process interventions which are used within harvesting and processing operations.

- Routinely verify the effectiveness of their food safety interventions by using microbiological testing methods recognized by the Food and Drug Administration (FDA) and U.S. Department of Agriculture (USDA).

- Verifies supplier programs through third-party audits, on-site inspections, and, where applicable, microbial testing.

- Conducts routine, often unannounced, on-site visits to suppliers’ operations to ensure that food safety culture is being practiced and remains abreast of what is happening “out in the field.”

- Shares best practices across ingredient suppliers, so that all are held to the same standards and receive credit for the food safety investments they make.

Source: https://www.chipotle.com/foodsafety

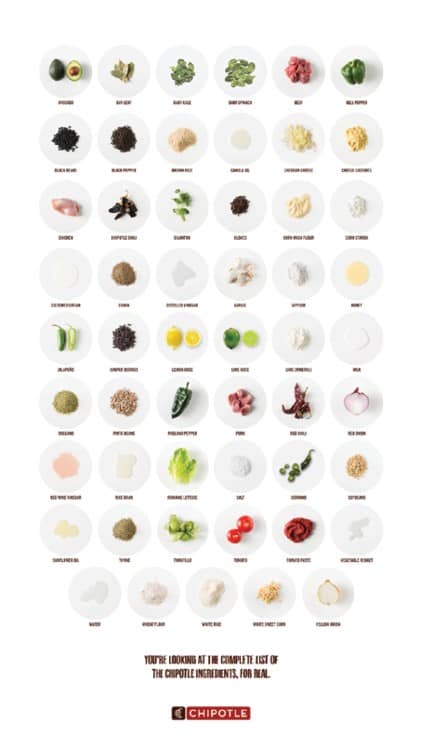

Chipotle is committed to preparing real food made with real ingredients. It makes its food fresh every day using 53 key ingredients consumers can readily recognize and pronounce.

Chipotle is committed to preparing real food made with real ingredients. It makes its food fresh every day using 53 key ingredients consumers can readily recognize and pronounce.

© Photo Courtesy: Chipotle

REMOVE RISK EARLY. With a key focus on “real” (“Real Ingredients. Real Purpose. Real Flavor”) and a commitment to making food fresh daily using no artificial colors, flavors, or preservatives, Chipotle uses “a ton of fresh produce”; has no freezers, microwaves, or can openers in its restaurants; and uses only 53 ingredients. So, both supply-chain and facility food safety are critical. But, Bridges said, “When you have only 53 ingredients, you have to get creative.” Particularly when they are 53 ingredients consumers can “recognize and pronounce,” as stated on Chipotle’s Values webpage.

Transparency of the supply chain is a key aspect of this, with Chipotle scanning every case of fresh produce that comes into its restaurants. Suppliers are required to identify each food item with a unique Global Trade Item Number (GTIN), and then label each case of ingredients following GS1 standards with a barcode containing the GTIN, lot number, and pack date or use-by date.

By scanning every case of refrigerated food at each point in the supply chain, Chipotle is able to track and trace every refrigerated ingredient at every restaurant back to the originating supplier at the lot code level.

In this way, “if there is an ingredient or product withdrawal, we can easily see which restaurants may have received the shipment,” Bridges said. She also can see very quickly which restaurants have executed a withdrawal — and which haven’t, “and get on the phone with them,” she said. That level of traceability and transparency also put the onus back on suppliers, growers, and farms to ensure the products they are providing are food safe.

While emphasizing the value that Chipotle places on transparency, Bridges also understands that there are challenges. But, she said, “My team is interested in partnering with suppliers to get through those challenges.”

With Chipotle having built this consistent traceability into its supply chain, Bridges sees it as only a matter of time until the entire food industry becomes just as consistent. “I see a light at the end of the tunnel for suppliers to be engaged and everyone asking the same thing,” she said. “I don’t see it taking 10 years; I see it moving quickly.”

For suppliers interested in partnering with them, she said, “Understanding Chipotle is really important.” Know its values, requirements and processes, and ensure that you are willing and able to reflect those (values). “We maintain a limited list of approved suppliers, many of whom are among the top suppliers in the industry,” she said.

Early risk assessment and removal once product arrives at Chipotle is focused on the use of natural antimicrobial wash of all produce, leveraging of inhibitors, and implementation of innovative processes. For each menu item, Bridges said, “We ask: What can we innovate? What can we do with this menu item to ensure food safety?”

Included among those is discontinuing the use of raw beef in the restaurants. Instead, the beef undergoes a sous vide process at the commissary level. The beef is placed in a vacuum-sealed package and heated at low temperatures for extended periods of time, which preserves the quality and consistency and provides a kill step for food safety. In the restaurant, the sous vide meat is then seasoned and grilled. Chipotle also blanches all fresh jalapenos, which are known to be high-risk produce, before they are diced for the salsas to reduce bacterial loads.

Chipotle has long been known for its focus on local food sourcing. Because this often involves small growers who may face obstacles in meeting the restaurant’s supplier requirements, Chipotle developed a Local Grower Support Initiative, through which it provides training and funding to small, local growers so they can implement programs to meet its standards of food quality and safety.

Chipotle supports its local growers by providing and covering the cost of facility improvements/design for food safety, food safety recordkeeping templates, and tools to help them comply with new regulatory requirements (e.g., the Produce Rule).

Earlier this year, Chipotle partnered with the National Young Farmers Coalition to offer 50 young farmers and ranchers $5,000 grants to start or grow their own business. More recently, Chipotle launched its Virtual Farmers’ Market, which allows farmers in its supply chain to launch improved versions of their own eCommerce websites.

Chipotle participated in the 2020 Rose Parade with a float, entitled “Cultivate the Future of Farming,” featuring a live post-to-donate element and reflecting its mission to cultivate a better world.

Chipotle participated in the 2020 Rose Parade with a float, entitled “Cultivate the Future of Farming,” featuring a live post-to-donate element and reflecting its mission to cultivate a better world.

© Photo Courtesy: Chipotle

“We invest in young farmers because they are the future,” Bridges said. “We help with training, and ask, ‘How can we help your program?’” But, regardless of size, every supplier has to meet Chipotle’s food safety requirements.

REDUCE RESTAURANT RISK FACTORS. Although it is not a typical foodservice practice, the company implemented HACCP in every restaurant, identifying critical control points (CCPs) and monitoring them. “That’s what we’re measuring, documenting, and training to,” she said.

To ensure the restaurant workers have a full understanding of, and follow, all food safety measures, Chipotle has instituted a wellness check before each shift at each restaurant. It also performs quarterly in-field training and is building out food safety teams in each region of operation to help support the restaurants in their food safety efforts.

To reduce the potential risk inherent in the food preparation conducted in the restaurants, such as ingredient chopping and dicing and guacamole making, there are now a limited number of employees who work with the prep. These teams of “culinary champions” come in in the morning to make the food, limiting the exposure of the food and the number of workers who touch it.

Similar to the five points of food safety implemented at Walmart while Bridges was there, she has developed a seven-point food safety list. The Top 7 Food Safety Things to Remember, posted in the restaurant kitchens as a visual reminder, include:

Increased communication helps federal, state, and local agencies see the effectiveness of Chipotle’s food-safety program and its dedication to food safety.

Increased communication helps federal, state, and local agencies see the effectiveness of Chipotle’s food-safety program and its dedication to food safety.

© Photo Courtesy: Chipotle

- Work healthy

- Work clean

- Keep produce safe

- Cook food to correct temperatures

- Hold hot and cold foods at specified temperatures

- Maintain sanitary conditions

- Call for help when needed

Since 2015, Chipotle has significantly increased the number of internal and third-party inspections of its restaurants, following the requirements of state and local health department inspections. These include unannounced third-party audits, intended to determine and understand any criticals that occur, particularly any repeat criticals.

Bridges’ team also reviews the health department inspections, both for any issues and to compare Chipotle’s results with other restaurants of its size; and Chipotle’s field operations team conducts food safety checks. The field leaders use a software application that allows for real-time visibility into task completion rates, from which they complete a comprehensive monthly review of the food safety standards at each restaurant. They also complete a shorter “Owners’ Path” assessment at each restaurant visit, auditing the location against Chipotle food safety standards.

With regular, real-time feedback from the inspections and audits, Chipotle is able to identify both best practices and areas needing improvement. “We have a lot of food safety communication with the field,” Bridges said. “There is a lot of visibility.”

MANAGE EMERGING ISSUES. With many of its food safety improvements incorporated to mitigate the chance of a norovirus outbreak recurring, Chipotle was ahead of the curve in developing protective practices for COVID-19. The restaurants were already conducting wellness checks and other practices to ensure workers stayed home when ill.

“No one can get into the kitchen without a wellness check, and we were doing that before COVID,” Bridges said. “If someone reports to work who is not feeling well, they are immediately sent home; and if a wellness check isn’t conducted and a supervisor is pressuring someone to work, “the result is termination,” she said.

To help maintain worker health and prevent incidents, Chipotle implemented a norovirus preventive program (NPP), for which it works with a third-party clinical team of three nurses to support its food-safety hotline team. Employees who experience a foodborne illness symptom are contacted by a nurse to make a determination about the NPP and employee exclusions. This process has since been expanded to include employees who may experience COVID-19 symptoms.

“So the team is trained for NPP,” Bridges said. “They understand how important it is to work healthy.” The company has enhanced some of its practices for COVID, such as increasing handwashing to once every 30 minutes from once an hour and adding masks and physical distancing. But, she said, “We did not have to introduce new language.” Workers were told to “keep doing what you’ve been doing.”

With increased health protections now a part the COVID-19 norm, “we’re hoping that the silver lining of all this is that people get the message,” Bridges said. “We’ve been pushing public health for so long, but now people understand how important it is to keep yourself and others safe.”

ENHANCE REGULATORY COMPLIANCE. Bridges sees having good relationships with officials at the regulatory agencies, such as CDC, FDA, and state and local health departments, as very important. Increased communication helps the agencies see the effectiveness of Chipotle’s food-safety program and its dedication to food safety. “Chipotle’s constant communication and interactions help ensure early alignment if there are potential concerns,” she said.

Similar to the five points of food safety implemented at Walmart while Kerry Bridges was there, she developed a seven-point food safety list at Chipotle Mexican Grill.

Similar to the five points of food safety implemented at Walmart while Kerry Bridges was there, she developed a seven-point food safety list at Chipotle Mexican Grill.

© Photo Courtesy: Chipotle

Public-private partnerships also enable Chipotle to share best practices it has developed to help the entire industry combat foodborne illnesses. Bridges has talked with CDC about all it has done to combat norovirus, and, she said, “I’m looking forward to that day I can sit down with them and discuss a solution.” Since there is currently no silver bullet to address it, they are doing everything they can to mitigate it and design risk out of the supply chain.

By also holding board seats and participating in technical working groups with associations, Chipotle food safety and quality assurance team members get the opportunity to learn and share knowledge and expertise with other food safety professionals as well as the regulatory agencies.

DRIVE GLOBAL CONSISTENCY. With more than 2,650 restaurants, the U.S. remains Chipotle’s stronghold, but it also operates 40 restaurants outside the U.S. in Europe and Canada — where it ensures consistent practices are in place.

And such consistency is proving to be of value. According to recent research, Chipotle is at the head of the class in food safety, having the least number of nonconformities of the brands the research agency studied. “It tells me that we’re very critical on ourselves — and we absolutely have to be; we have to be the leader,” Bridges said.

CULTIVATE FOOD SAFETY. “Food safety culture is something we put in our strategy to keep the message alive,” Bridges said. In addition to the practices discussed earlier in this article, Chipotle makes a point of investing in its people — both in the field and in the support center — to help them grow.

“I don’t know if everyone realizes how much has gone into these programs and what is happening today,” she said. “But it’s a journey. It’s been a journey and will continue to be.

There is a lot of innovating in the food safety space, and Chipotle is always one to raise our hands and say, ‘Let’s try it,’” she said.

There will always be scenarios when it is difficult to determine what should be done. But, when these come up, Bridges said, she remembers the sage advice of Yiannas, who said, “When you don’t know what to do, do what you know to do.… Go with your gut, with public health in mind.”