Around once a second wing of food insects collide with small obstacles such as flowers, leaves or twigs in flight without suffering major long-term damage. Photo credit: Stanislav Gorb

Around once a second wing of foraging bees collide with small obstacles such as flowers, leaves or twigs in flight without suffering major long-term damage. At the same time, they easily withstand aerodynamic loads – but the fragile structures only make up two percent of the total mass of an insect’s body. Scientists from the Zoological Institute of the University of Kiel (CAU) are investigating how insect wings can withstand these different demands without breaking. In an article in the current issue of Advanced Science, they show some peculiarities of the wing structure, thanks to which they are both stable and flexible and can therefore adapt to different needs. In the long term, these construction strategies could lead to the development of structural elements that are load-bearing, durable and impact-resistant at the same time and enable various applications in the fields of robotics, aviation or biomedicine.

Technical structures often only fulfill one of the two properties: Either they can withstand high loads – such as B. stable load-bearing components in buildings – or they are durable and flexible and give in to external influences such as a collision so as not to break. If both capabilities could be combined, “variable stiffness” structural elements could be developed that function more efficiently by changing their malleability in response to changes in their external environment. However, previous studies use complicated and costly approaches that make them difficult to use in everyday applications.

Three elements in the design of the insect wings allow flexible adaptation

“What the engineering community is currently moving has already been perfected by insects: thanks to a special design, their wings can assume different degrees of flexibility depending on the situation,” says Professor Stanislav Gorb from the “Functional Morphology and Biomechanics” working group. “Summary of the results of the study. So far, biological research on insect wings has mainly focused on aerodynamic aspects. Despite this trend, the researchers at the Zoological Institute instead looked more closely at the structure of insect wings, here dragonfly wings. For the first time, they combined three different structural elements the wing structure with its function: They ensure that collisions and wind forces cannot damage insects during their flight: flexible joints, mechanical stoppers and kink zones.

Photo credit: University of Kiel

Dragonfly wings are made up of a rigid network of veins and membranous areas between them. The veins are connected by flexible joints. This allows the wings to deform under relatively low loads. At higher loads, microscopic tips close to the micro-connections interlock and stop the deformation. They increase the rigidity to support the wing against aerodynamic loads. And finally, special zones in the wing buckle reversibly to a certain extent in the event of a collision with an obstacle. “Thanks to these three design strategies, insects can change the properties of their wings and thus fulfill several functions at the same time,” says Ph.D. Student Ali Khaheshi, lead author of the study.

Three structural design elements of the wing structure ensure that collisions and wind forces cannot damage insects during their flight: flexible joints, mechanical stoppers and kink zones. Photo credit: Hamed Rajabi

Successful transfer of design strategies to an airplane model

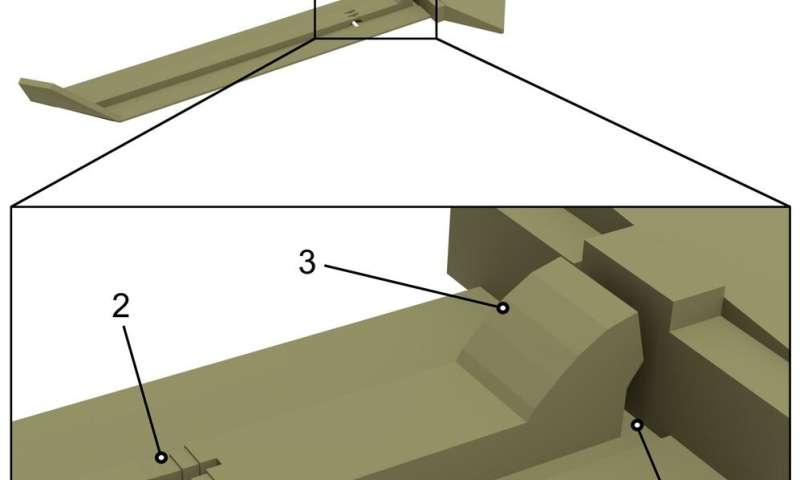

However, the research team went one step further: to test whether their theory about insect wing design strategies would hold up in practical application, they applied it to an airplane model measuring 8 x 5 x 1.1 cm and weighing 3 , 8 to G. They 3D printed it from PLA / PLH filaments and performed both collision and free fall tests. It turned out that the wings survived the collisions, while conventionally constructed aircraft models broke. In addition, they performed static, dynamic, and fatigue tests on slightly modified designs, each of which omitted one of the design strategies. “These experiments confirm that all three design strategies must be combined in order to achieve the observed mechanical performance,” says the engineer and materials scientist Khaheshi. According to the researchers, this could also work with other higher quality materials.

-

Scientists also applied the design strategies of insect wings, (1) flexible joints, (2) kink zones, and (3) mechanical stoppers to a model airplane. Photo credit: Ali Khaheshi

-

The model was 3D printed with a size of 8 x 5 x 1.1 cm and a weight of 3.8 g and subjected to both collision and free fall tests. Photo credit: Ali Khaheshi

The main point is that the strategies are already built into the structure of the wings and function completely passively. Complex control strategies are not required. “Such findings from biology could help us to construct technical systems that adapt autonomously to extreme or unforeseen situations – for example in environments in which humans cannot actively intervene, for example in space missions,” says Dr. Hamed Rajabi.

The research team develops joint splints for sports and medicine that are inspired by dragonfly wings

More information:

Ali Khaheshi et al. Triple Stiffness: A Bio-inspired Strategy for Combining Load-bearing Capacity, Durability, and Impact Resistance, Advanced Science (2021). DOI: 10.1002 / advs.202004338 Provided by the University of Kiel

Quote: How insect wings withstand collisions without breaking (2021, March 22), accessed March 23, 2021 from https://phys.org/news/2021-03-insect-wings-collisions.html

This document is subject to copyright. Except for fair trade for the purpose of private study or research, no part may be reproduced without written permission. The content is provided for informational purposes only.

/https://tf-cmsv2-smithsonianmag-media.s3.amazonaws.com/filer_public/97/03/97033d57-bf5f-4165-bb93-e2bfe01357c9/p-ant-lab-experments_web.jpg)